Asymmetrical competitions in today’s rapidly changing industrial environment dictate the need for valves that are not only of high quality but also vary in design and purpose to meet the functional requirements of the industries. Valves used for oil and gas industries, petrochemicals, power plants, and water treatment industries are in high demand due to increasing need for quality, safety, and environmental control. Consequently, comprehensive valve solutions are seen as one of the key factors for successful and uninterrupted industrial processes. This article is aimed at describing how innovation, technology and specialization help to satisfy unique requirements of the industry in terms of the latest valve offerings.

New Valve Development

Valves solutions are used in the industrial sector to control, transport, and direct fluids, gasses and slurries through pipes and systems. New technologies are vital when it comes to competing in a challenging market and this is why the ability to design new value technologies is vital. New valve designs, manufacturing technologies, and material knowledge enable improved reliability, performance and economy of valves.

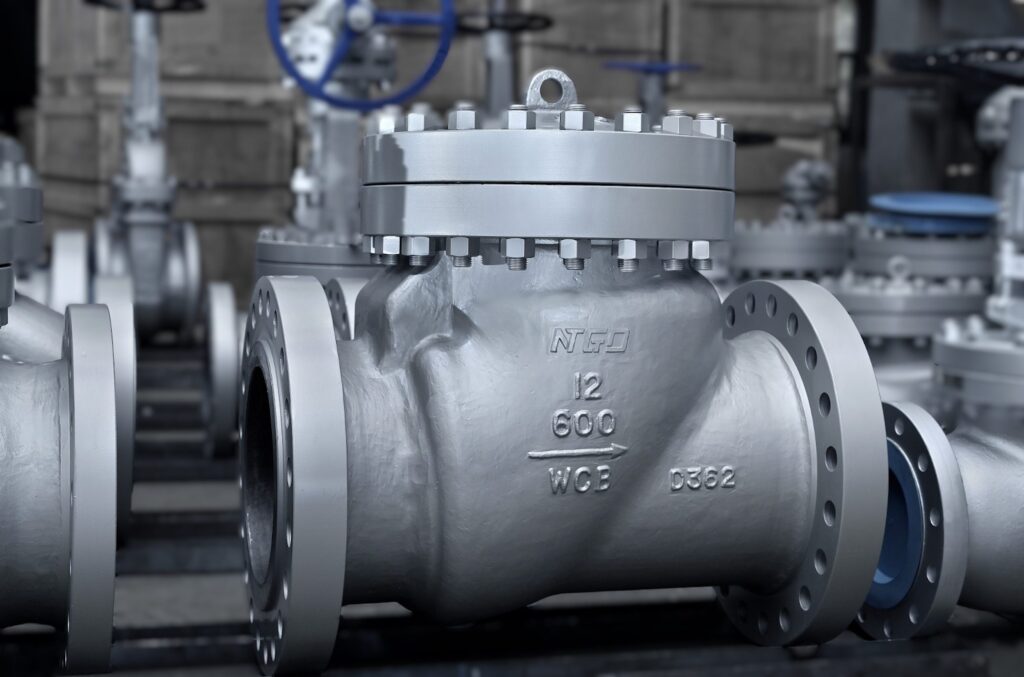

The industrial valve manufacturers are incorporating sophisticated technologies in an effort to design and develop valves that will operate under high and additional pressure, temperature, and corrosion conditions. For example, swing check valve producers are developing valves that allow unimpaired flow with minimal reverse flow impact, which is suitable for the petrochemical processing and water management industries.

The concept of innovation also does not end at the product level. Real-time monitoring of smart valves that are connected with IoT (Internet of Things) technology are changing the ways in which enterprises oversee their facilities. Remote diagnostics, conditions-based maintenance, and automated control enhance control of the valve assets, making it possible for organizations to minimize control loss, and decrease operating costs while increasing safety.

Responsive to the contingencies of Industry

Owing to the ability to make adjustments to the products for industry needs, comprehensive valve solutions play a significant role in industries. Various industries encounter problems that regular valves could not solve adequately. For example, in an oil refining industry the valves must be suitable for high pressure and high temperature; however in the water treatment industry the valves should be very much resistant to corrosion and contaminants.

Valve manufacturers also can offer industry-specific solutions for the process equipment, which means better performance and effective service life of the equipment. Here, clients are engaged to determine their operating difficulties before a thorough design and testing cycle is embarked upon in order to manufacture exceptional quality valves.

Swing check valve manufacturers are a valuable partner for companies in need of all-encompassing valve solutions tailored for the requirements of a particular industry. Customization helps to give valves made for the application and for performance within the specific environments that the businesses operate in.

Strict Quality Control

Its quality assurance is an essential part of valve manufacture, especially if valves are to be used in settings where they must not fail since people’s lives may be at risk. An adequate valve package cannot be limited to simply assuring that every valve complies with all the relevant industry specifications; it must assure that all valves will operate as required, no matter the conditions.

Having competitive advantage, first-rank global valve suppliers carry out strict quality control measures with third party inspections and tests in accredited laboratories. Every valve is tested to determine whether it meets operating requirements and is then shipped to customers. The tests may involve a pressure-checking test, material-test, and testing of the valve under extreme working conditions.

Regarding industrial valve suppliers The delivery of high-quality valves is mandatory because a valve failure in the field may lead to additional costs, environment pollution, or even failure of the complete system. When quality is given the priority, the supplier creates confidence in the business and the two partners are in it for the long run.

Facilitating Operations

Valves are important components that increase the sense of operating efficiency. From keeping the flow rates as desired, regulating pressure, or checking the correct functioning of a system, a good valve system will go a long way in the day to day functioning. When sourcing industrial valves from reliable industrial valve suppliers companies can be assured of precise control of processes, reduced downtime, and lower energy use.

Effective valve solutions also help to prolong equipment life, since well maintained and accurately regulated valves do not overstress the systems they supply. This in turn affects the total cost of ownership because you don’t have to replace the part so often or pay to have it repaired. As the business world shifts towards meeting sustainability needs at a lower cost, comprehensive valve solutions are a necessity.

Besides operation efficiency, there are enhanced modern valve systems that have been designed to ensure energy efficiency. For instance, control valves used on steam or gas in power plants utilize minimum energy storage as a design criterion to enable savings on fuel consumption and promote environmentally friendly processes.

Future Trends in Valve Solutions

From the perspective of the future, the developments of automation, material, and environment are key factors for the valve solutions. Over time, new and better technologies and standards will emerge and with them the need for valves that are smarter, more efficient, and sustainable. Here are some trends shaping the future of valve solutions:

1. Automation and Smart Valves: With the growing adoption of IoT and automation, more and more valves will have sensor and reporting systems in their central stations. While above smart valves refer to the ability to be operated remotely and the possibility to collect data in real time which will help in defining proper time for maintenance and increase operational effectiveness.

2. Sustainability Focus: The pressure towards making all products sustainable across various industries will mean that valve manufacturing industries will have to shift their attention towards making their products energy efficient and friendly to the environment. Energy savings, anti-waste, anti-leakage valves will occupy a significant place in the demand.

3. Advanced Materials: Development in the field of materials science will result in the design of valves that are less susceptible to corrosion, wear, or high operating temperatures. Such materials will increase the durability of valves and decrease frequency of maintenance, which will be beneficial for businesses.

Therefore, to cater for all the needs of different sectors, complete valve arrangements are crucial. Value-driven innovation, value addition, and quality assurance are some of the factors which make a valve supplier produce valves that can function under various conditions. Through collaborating with skilled industrial valve suppliers and swing check valve manufacturers, different businesses can improve their performance, safety, and adaptability to the future tendencies in the industry.